Your current location:Home >>Product Center >>Ceramic ring

Hits:3647 Time:2020-01-16

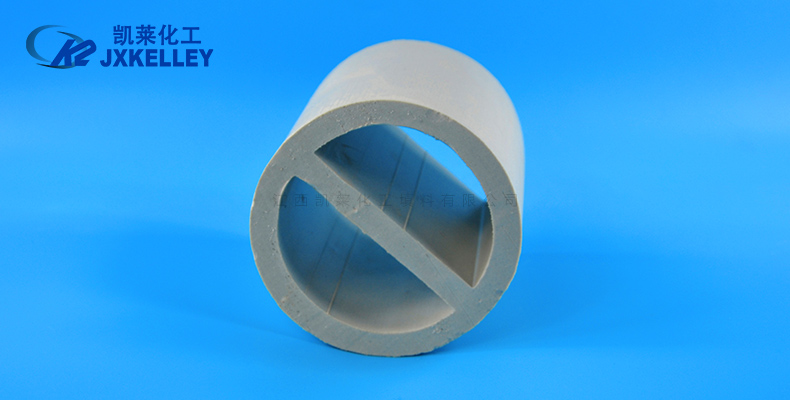

Ceramic ring is a word formed from ceramic raschig ring improved, than ceramic raschig ring has a larger specific surface area and better compressive strength, has excellent acid resistance and heat resistance, can and ability of various inorganic acid, organic acids except hydrofluoric acid and organic solvent corrosion, and can be used in high temperature or low temperature environment, so its use range is very wide. Ceramic ring can be used in drying tower, absorption tower, cooling tower, washing tower in chemical industry, metallurgy industry, coal and natural gas industry, industrial oxygen production industry, in the process of mass transfer applications as tower packing, in heat exchange heat storage incinerator as heat transfer medium. This product is made by calcination one day and one night. The sintering temperature is above one thousand degrees. It is an inert product.

● ceramic word ring internal added structure is symmetrical, with the center of the whole packing as the symmetrical point, to both sides to make the length and width are the same straight plate design, so that the structure of the packing can be more stable, so as to ensure that when working can also have stable properties and functions. This has a certain test for the production capacity of the manufacturer, at the beginning, not all manufacturers have such capacity. Later, when the product was gradually popularized, more manufacturers began to produce zigzag rings, providing a large number of market demand.

● ceramic ring stacking is not regular, and the addition of a word ring increased its internal space, resulting in a larger volume, now the factory will use it more as an auxiliary filler in the lower part of other fillers, to protect the upper filler. Reducing the degree of acid and alkali corrosion of other fillers, especially in the gas environment, plays a good protective role.

| SiO2 + Al2O3 | >92% | CaO | <1.0% |

| SiO2 | >70% or >47% | MgO | <0.5% |

| Al2O3 | >17-23% or >23~45% | K2O+Na2O | <3.5% |

| Fe2O3 | <1.0% | Other | <1% |

| Bibulous rate | <0.5% | Mohs | >6.5 scale |

| porosity | <1% | Acid resist ance | >99.6% |

propo rtion | 2.3-2.40 g/cm3 | Alkali resis tance | >85% |

Maximum operating temperature | 1200℃ | / | / |

| size | Outside diameter inside diameter height thickness | Packing weight | number | area | factor |

| mm | kg/m3 | Pcs/m3 | m2/m3 | m-1 | |

| 10mm | 10*6*8*2 | 800 | 750000 | 420 | 1250 |

| 50mm | 50*40*50*5 | 600 | 6500 | 145 | 565 |

| 80mm | 80*64*80*8 | 820 | 1950 | 120 | 356 |

| 100mm | 100*80*100*10 | 850 | 1000 | 110 | 252 |

| 120mm | 120*96*120*12 | 860 | 370 | 75 | 146 |

| 150mm | 150*120*150*15 | 980 | 296 | 60 | 10 |

Pre page: 无

Next page:无