Your current location:Home >>Product Center >>Plastic lampak

Hits:5641 Time:2020-01-16

Lampax has a large porosity and surface area that is ideal for the biological treatment of potable water. Biofilm is a good treatment process for raw water containing ammonia, manganese, iron, etc. Lampax can be used in different ways during the traditional filtering process. Dual filters in the media can be used in combination with sand. Tests have shown that lampl operates or performs better filtration in these types of filters than conventional fillers. Lampak can be used not only for traditional drinking water treatment, but also for brine treatment. One of the most important parts of a desalination plant is the pretreatment process. Lampak is a good filter medium for the pretreatment and filtration of desalination plants.

● lampak packing is used to solve the problem of formaldehyde alcohol/water distillation for pharmaceutical manufacturers. With lampak packing, the feeding speed can be doubled, the pressure drop can be reduced, and the mass transfer efficiency can be improved.

● lamparc packing can increase the gas flow rate in the pulp mill using Cl2/ClO2 technology to bleach the pulp scrubbing tower by 40%;

● lamparker packing can remove groundwater polluted by dry washing fluid in PCE air-lift packing tower has been proved to have obvious advantages. The content of PEC in the treated water through PCE gas-filled column is less than 5mg/L, which is suitable for tap water.

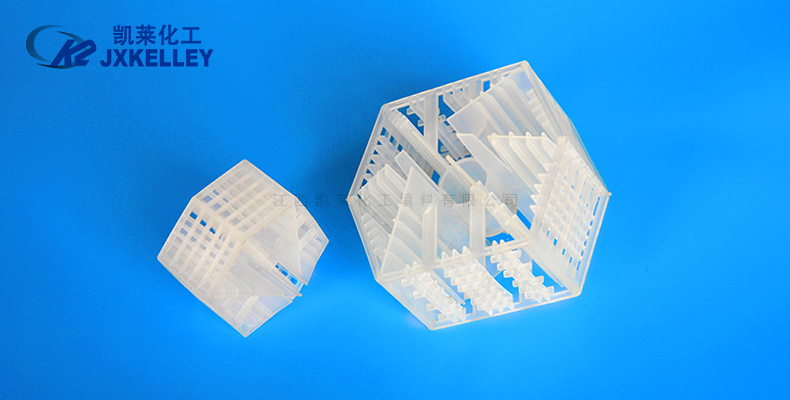

Low LAN parker packing by six of the same diamond inscribed in a circle combined into a six diamond rings, each of the six ling ring can be seen as a small structured packing, and USES the smaller diameter ratio high, can lead to the structured packing arrangement when loading, make its have bulk packing characteristics of low cost, easy handling and maintenance, and structured packing mass transfer the advantages of high efficiency, low pressure drop. It is a high efficiency, high flux, low pressure drop and low cost bulk packing.

| name | Plastic lampak | ||||

| material | PP, PE、PVDF. | ||||

| size | propo rtion | Dry packing factor | |||

| mm | area | Void | number | Kg/m3 | m-1 |

| m2/m3 | % | per/ m3 | |||

| 90 | 144 | 92.5 | 1765 | 4.2lb/ft3 67kg/m3 | 46/m |

| 60 | 222 | 89 | 7060 | 6.2lb/ft3 99kg/m3 | 69/m |

Pre page: 无

Next page:无