Your current location:Home >>Product Center >>Honeycomb ceramic heat accumulator

Hits:5756 Time:2020-01-15

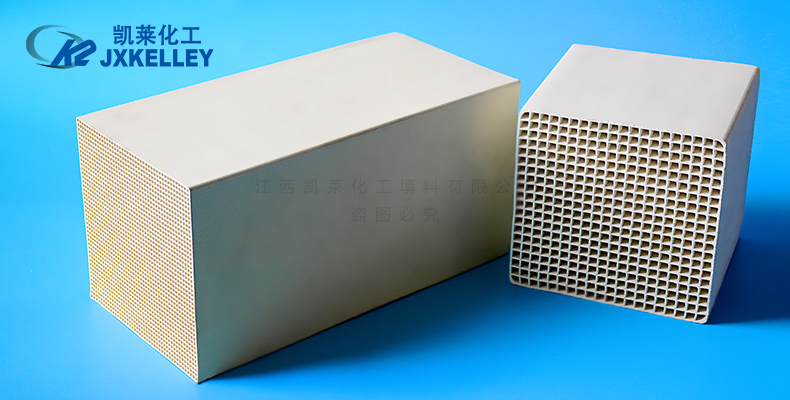

Honeycomb ceramic heat storage body has the remarkable advantages of high temperature resistance, corrosion resistance, good thermal shock stability, high strength, large heat storage, good thermal conductivity and so on. Regenerative high temperature air combustion is a huge energy saving and environmental protection effect of new type of combustion technology, honeycomb ceramic regenerator are key components of regenerative burner, it is widely used in iron and steel, machinery, building materials, chemical, petrochemical, paint, non-ferrous metal smelting and other industries of all kinds of heating furnace, hot stove, heat treatment furnace, furnace, baking equipment, melting furnace, soaking furnace, oil and gas boiler and so on in the kiln. The technology through the reversing device makes two endothermic heat regenerator alternation, large heat recovery of flue gas, and the furnace combustion air and gas heated to 1000 ℃ above, even inferior fuel of low calorific value can realize stable and efficient combustion fire, can save fuel 25% to 30%, yield increased by more than 15%, fell by more than 40%, oxygenation loss of billet NOx emission is less than 100 PPM emission of flue gas temperature is below 150 ℃, greatly reduce the greenhouse effect of the earth's atmosphere. If most industrial kilns in China adopt HTAC technology, its economic and social benefits are immeasurable, which will greatly alleviate the situation of energy shortage and greatly improve the living environment of human beings.

● honeycomb heat accumulator has the advantages of large heat exchange area per unit volume, fast heat transfer, small airflow resistance, shallow diathermy depth and high thermal efficiency. There are square hole, round hole, hexagonal hole and other types of holes and plane, bevel, single groove, double groove wall shape. High refractoriness, high softening temperature under load, good slag resistance, good thermal shock stability, fast heat conduction, good scour resistance, large capacity, large heat capacity and other advantages, the added catalyst in 600℃ or so with the CO, HC compounds catalytic combustion, further improve the recovery of waste heat and reduce the emission of pollution gas.

| project | unit | num erical |

Bulk density | g/cm3 | 1.7~2.0 |

| Specific | (J/Kg.k)(20~1000℃) | 900~1150 |

| Thermal | (20~1000℃) | 1.2~1.8 |

| shock | (℃/min) | ≥350 |

| High | ℃ | 1320 |

| rate | % | 15~25 |

Pre page: 无

Next page:无