Your current location:Home >>Product Center >>Ceramsite filter material

Hits:5682 Time:2020-01-15

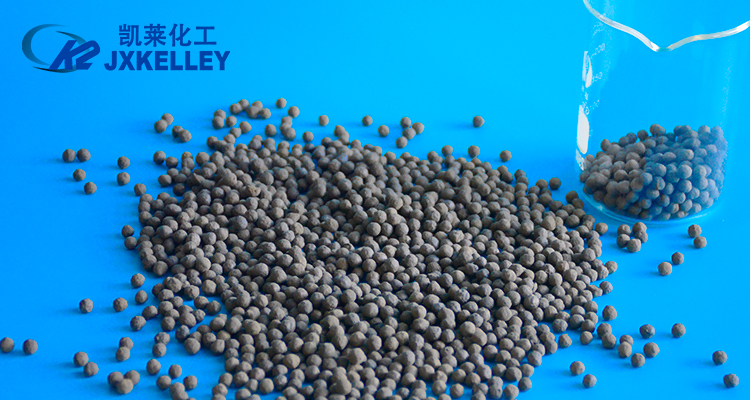

Ceramsite filter material is made of high quality clay, adding pore-forming agent and adhesive solvent, through ball grinding, screening, molding and calcination. Its surface is hard, internal microporous, with a large specific surface area, high voidage characteristics. Used in water treatment, it has the characteristics of strong intercepting capacity, long filtration period, small filtration head loss, low backwash water consumption and so on. It is a new filter material that can increase water production, improve water quality and save energy consumption. Precipitation, coagulation and biological ceramsite filtration are commonly used in wastewater treatment and tap water treatment.

● round, uniform, rough surface, multiple micropores, developed internal pores, large specific surface area, so that the biological bacteria has strong adhesion ability, rapid reproduction, high film hanging efficiency, under low temperature and low turbidity conditions, ammonia nitrogen removal effect reaches the domestic level, long working cycle, large periodic water yield, generally 500-1000m/m.

● light bulk density, high strength, thus low energy consumption for backwashing, small head loss, cleaning material head loss is only 150mm/m.

● strong decontamination ability, generally 9-13kg/m.

| project | unit | indicators |

| size | mm | 0.5-32 |

| proportion | g/cm3 | 2.26 |

| porosity | % | 55 |

| Wear rate | % | 1.62 |

| Coefficient | % | K80=1.84 |

| coefficient | % | K60=1.47 |

| soluble | % | 2.83 |

| Sodium | % | 1.5 |

Pre page: 无

Next page:无