Your current location:Home >>Product Center >>Plastic different saddle ring

Hits:3555 Time:2020-01-16

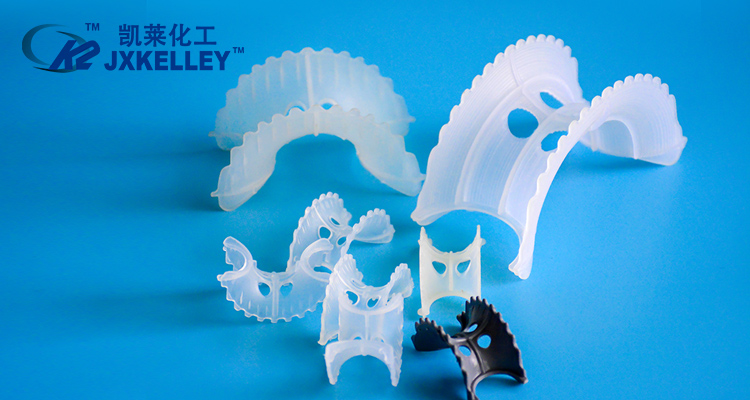

In the 1970s, the American Noton company made an improvement on the ordinary rectangular saddle ring packing by changing the fan arc surface into serrated shape and adding holes on the saddle back. In this way, the channel inside the packing layer was more smooth, which improved the liquid distribution performance, reduced the gas resistance and improved the mass transfer performance. Different saddle-ring plastic saddle-type packing is similar to the shape of a saddle. This packing layer is mainly composed of arc-shaped liquid channels. The interstitial space in the packing layer is more continuous than that in the ring packing (especially in the ring packing).

● plastic different saddle ring packing has the characteristics of large void, low pressure drop and mass transfer unit height, high flooding point, adequate vapor-liquid contact, small specific gravity, high mass transfer efficiency, low pressure, large flux, high efficiency, load elasticity, good anti-fouling, etc. Widely used in petroleum, chemical industry, chlor-alkali, gas, environmental protection and other industries in the packed tower, such as dewaxing oil refined extraction, demethanation, benzene anhydride refined.

Plastic different saddle ring is an improvement on the rectangular saddle ring. It is characterized by the improvement of the fan arc surface into the shell arc surface with serrated edge, and the addition of holes to make the internal and external surfaces of the packing to connect, increase the free channel of the fluid, which is conducive to the liquid distribution and surface renewal, so the processing capacity is higher than that of the rectangular saddle ring, and the pressure drop and mass transfer performance is improved. It is usually made of ceramic and plastic.

| name | Plastic different saddle ring | ||||

| material | PP/RPP/PVC/CPVC/PVDF,etc | ||||

| life | >3 years | ||||

| size | area | Void | number | Packing | packing factor |

| mm | m2/m3 | % | per/ m3 | Kg/m3 | m-1 |

| 25×12.5×1.2 | 260 | 90 | 51200 | 92 | 390 |

| 38×19×1.2 | 178 | 96 | 25200 | 75 | 201 |

| 50×25×1.5 | 168 | 97 | 6300 | 76 | 184 |

| 76×38×2.6 | 130 | 98 | 3700 | 64 | 138 |

perfor mance | High voidage, low pressure, low height of mass transfer unit, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency | ||||

advan tages | 1. The special structure makes it have large circulation, low pressure and good mechanical strength. | ||||

| 2. Strong corrosion resistance, large void ratio, energy saving and environmental protection, low cost, light specific gravity easy loading and unloading. | |||||

| field | Plastic bulk packing with a temperature of 280 degrees Celsius, widely used in petroleum, chemical, chlor-alkali, gas, environmental protection and other industries in the packed tower. | ||||

Proper ties mater ials | PE | PP | RPP | PVC | CPVC | PVDF |

| density | 0.98 | 0.96 | 1.2 | 1.7 | 1.8 | 1.8 |

Oper ating | 90 | >100 | >120 | >60 | >90 | >150 |

Corro sion resist ance | GOOD | GOOD | GOOD | GOOD | GOOD | GOOD |

stre ngth | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 |

Pre page: Heteromorphic saddle ring

Next page:无