Your current location:Home >>Product Center >>Plastic step ring

Hits:3792 Time:2020-01-16

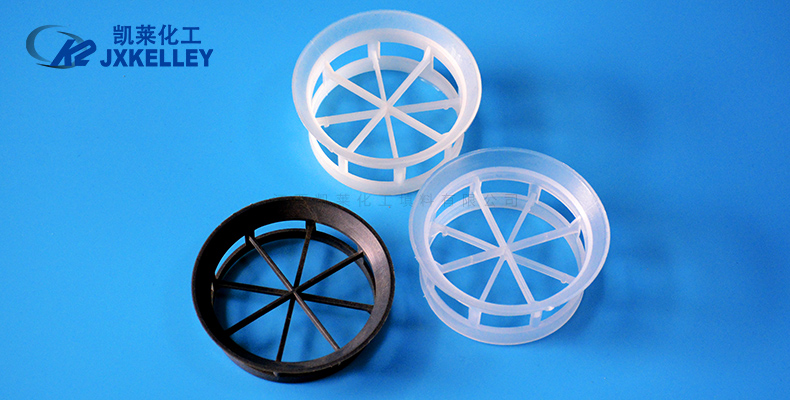

The material of plastic step ring is PP, PE, PP, PVC, CPVC, PVDF and other materials. It is invented by MTL company in Britain, so it is also called CMR. The side of the plastic step ring packing increased flanging, not only can increase the mechanical strength of the packing ring, but also because the plastic step ring packing once destroyed the symmetry of the packing structure, so increased the probability of the placement of the packing. In addition, because of the influence of flanging, the contact between the packing annulus of the stepped ring packing was changed from linear contact to point contact. Therefore, the stepped ring packing not only increases the space between the packing particles and reduces the resistance of the gas through the packing layer, but also these contact points can be the convergence and dispersion points for the liquid flowing along the packing surface, thus promoting the surface renewal of the liquid film and improving the mass transfer efficiency of the packing.

● large flux and small pressure drop: due to the packing structure and filling characteristics, the gas channel in the packing layer is more uniform and the return path is shorter, so the pressure drop of the packing layer is not increased when the gas flux of the coating layer is increased.

Low efficiency: the flanging of the plastic ladder ring packing not only can increase the gap filler layer, and make the gap even, is beneficial to uniform gap liquid on the surface of packing form a uniform and more effective liquid membrane, provide steam, liquid good channel, does not exist in pall ring or saddle packing surface or dry surface, thus ladder ring packing and mass transfer efficiency is higher compared with the above two kinds of packing.

● high operating flexibility: because the stepped ring packing greatly improves the liquid distribution and gas-liquid contact condition inside the packing layer, the operating range has a long increase, and the L/G can be operated within the range of 50-0.05.

| name | Plastic step ring | ||||

| material | PP,PE,PVC,CPVC,PVDF ,etc | ||||

| life | >3 years | ||||

| size | area | Void | number | weight | packing |

| mm | m2/m3 | % | per/ m3 | Kg/m3 | m-1 |

| 16*8.9*1 | 370 | 85 | 299136 | 135.6 | 602.6 |

| 25*12.5*1.2 | 228 | 90 | 81500 | 65 | 312.8 |

| 38*19*1.2 | 132.5 | 91 | 27200 | 54 | 175.8 |

| 50*25*1.5 | 114.2 | 92.7 | 10740 | 43 | 143.1 |

| 76*37*2.6 | 90 | 92.9 | 3420 | 44 | 112.3 |

perfo mance | High voidage, low pressure, low height of mass transfer unit, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency | ||||

advan tages | 1. The special structure makes it have large circulation, low pressure and good mechanical strength. | ||||

2. Strong corrosion resistance, large void ratio , energy saving and environmental protection, low cost , light specific gravity easy loading and unloading. | |||||

Appli cation field | The use temperature of plastic bulk packing is 280 degrees Celsiu s, widely used in petroleum, chemical, chlor-alkali, gas , environmental protection and other industries of the packed tower. | ||||

Prope rties mater ials | PE | PP | RPP | PVC | CPVC | PVDF |

| density | 0.98 | 0.96 | 1.2 | 1.7 | 1.8 | 1.8 |

tempe rature | 90 | >100 | >120 | >60 | >90 | >150 |

Corr osion | GOOD | GOOD | GOOD | GOOD | GOOD | GOOD |

stre ngth | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 |

Pre page: 无

Next page:Metal step ring