Your current location:Home >>Product Center >>Plastic lacey ring

Hits:3832 Time:2020-01-16

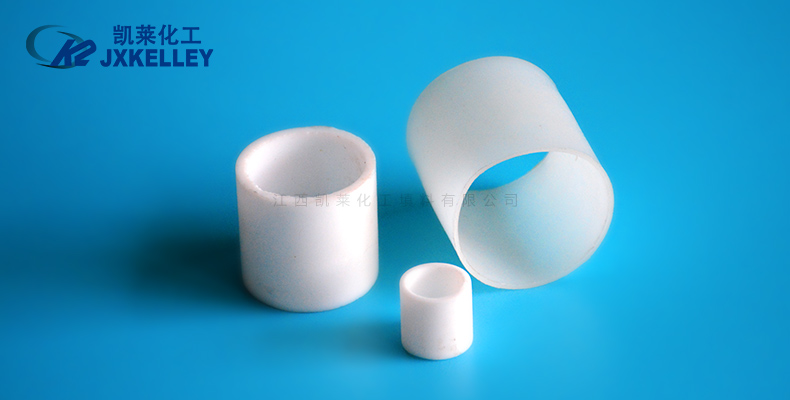

The plastic rasch ring is a loose packing. The shape is simple. It is a circle whose height is equal to its diameter. Rasicyclic ring has excellent resistance to acid and heat, resistance to various inorganic acids, organic acids and organic solvents except hydrofluoric acid corrosion, can be used in a variety of high temperature occasions. Plastic ring fillings are mainly divided into: polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyvinylidene fluoride (PVDF), chlorinated polyvinyl chloride (CPVC), reinforced polypropylene (RPP), etc. According to different requirements, the materials used are different, the commonly used ring is pp ring, PVC ring, RPP ring and so on. Plastic ring packing applications are very wide, can be used in chemical industry, metallurgy, gas, environmental protection and other industries drying tower, absorption tower, cooling tower, washing tower, regenerated tower.

Plastic ring is the earliest ring packing with fixed geometry in the history of tower packing

● simple structure, low price, but there are uneven liquid distribution and serious wall flow channel flow phenomenon.

● corrosion resistance can also withstand kingwater and all organic solvents; Optimum aging life in weather resistant plastics; High lubrication with minimum friction coefficient in plastics (0.04); Having the smallest surface tension in a solid material and not adhering to any substance; nonviscous. Non-toxic with physiological inertia; Excellent electrical properties, is the ideal grade C insulation material. Widely used in national defense, atomic energy, petroleum, radio, electric machinery, chemical industry and other important departments.

| name | Plastic lacey ring | ||||

| material | PP, PVC, CPVC, PVDF, PTFE, PE. | ||||

| life | >3 years | ||||

| size | area | Void | number | weight | Dry packing |

| mm | m2/m3 | % | per/ m3 | Kg/m3 | m-1 |

| 16 | 260 | 91 | 171000 | 94 | 490 |

| 25 | 205 | 90 | 50000 | 112 | 400 |

| 38 | 130 | 89 | 19000 | 70 | 305 |

| 50 | 93 | 90 | 6500 | 68 | 177 |

| 80 | 90 | 95 | 1820 | 66 | 130 |

perfo rmance | High voidage, low pressure, low height of mass transfer unit high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency | ||||

| merit | 1. The special structure makes it have large circulation, low pressure and good mechanical strength. | ||||

| 2. Strong corrosion resistance, large void ratio, energy saving and environmental protection, low cost, light specific gravity easy loading and unloading. | |||||

Appli cation field | The maximum use temperature of plastic bulk packing is 280 ℃, which is widely used in petroleum, chemical, chlor-alkali, gas, environmental protection and other industries. | ||||

Prope rties mater ials | PE | PP | RPP | PVC | CPVC | PVDF |

| Density | 0.98 | 0.96 | 1.2 | 1.7 | 1.8 | 1.8 |

| Operating | 90 | >100 | >120 | >60 | >90 | >150 |

| Corrosion | GOOD | GOOD | GOOD | GOOD | GOOD | GOOD |

| strength | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 |

Pre page: Corundum ring

Next page:Metal ring